Disclaimer:

This modification is not approved by Pertronix.

When I bought my Pantera

in 1998 it had an Accel

model 30202 dual point distributor installed.

The 30202 was designed for racing applications and has

the ability to operate at

very

high RPM using points. This is

accomplished with a special bearing that holds the distributor shaft above the

cam, centrifugal advance only and uses points with very heavy spring pressure

to prevent point bounce at high RPM. The

distributor worked very well but the race application points wear pretty fast, requiring ongoing

dwell adjustment and frequent point

replacement. For the last few

years I've

wanted to change out the points for some type of electronic unit but none of

the electronic manufacturers made a conversion kit for the 30202.

I could have just replaced the distributor with a new electronic one,

but because I did not build the engine, I do

not know if the oil pump drive shaft

was installed correctly.

So

removing the distributor could have resulted in the drive shaft falling off

the distributor into the pan.

I knew that the Accel

distributor had some parts that interchange with GM 60s vintage

distributors and after some research I discovered that the 30202 points form

factor is very close to GM points. After

reviewing my options for an electronic unit, I decided the new Pertronix

Ignitor III would be the best unit for

my distributor

modifications. It was small, thin,

used a reluctance head and had great features. It looked like with a few

modifications it would work.

I have spare 30202s that

allowed me to develop and workout the modifications on the bench and then

install the Ignitor III in the

existing distributor that was in the

car. The following are the

modifications to install the Ignitor III.

View

of a

spare the Accel 30202

before disassembly.

In this view, the 30202

has been disassembled down to the point support plate. The two nearest mount

holes in the plate have been counter sunk with a drill bit and the screws

replaced with flat head screws. The original retaining studs for the secondary

points were reused but thicker washers used to take up the space of the

missing points plus one more thin washer so the bearing plate will clear the

top of the Ignitor

III

reluctance head.

View

of the top side of the Ignitor III GM adapter plate that comes with the Pertronix

kit.

The

lower side of the adapter plate requires modification in two places to make

clearance for the nub that helps hold the points in place and the nub for the

condenser mount. I elected to

modify the adapter plate rather than grinding the nubs off.

View

of the GM adapter installed. It

does not fit symmetrically around the cam but that is not a problem.

View

of Ignitor III

(Pertronix

part number 71181). I added longer

wires with disconnects and a plastic loom so I could run the wires along the

firewall.

View

of the Ignitor III installed in

the space where the primary points

were located.

At

this point

in the process

I carefully checked the reluctance

head clearance with the high points

on the cam. Pertronix

told me that

the reluctance head should be within .025 of the high points or as close as

possible without touching. Mine

came out around .012. Ignitor III mounting plate holes have a little play in

them so by default it

can be moved around a bit.

Note the height of the reluctance head in the center of the Ignitor III

and the fact that it will be close to the bottom of bearing plate.

I

decided

to cut off the

arm of the bearing plate that is in

the way of the Ignitor III. The

bearing plate feels secure with just two mounting locations and without the

points,

the side

force on it is light.

I guess it would be possible to run without the plate but I felt that

it would be better to retain the plate.

Another view. I decided to use the Pretronx Blaster III coil that is a very low resistance (.32 ohms). The coil is designed for the Ignitor III and capacitive discharge systems and the coil is NOT compatible with points.

Follow

the Pretronx

instructions for setting the Rev limiter, wiring and installation. The

ballast resister must be removed to

use the Ignitor III.

Just

in case, I made an emergency

back up kit with a single primary

point set, condenser, wires, hardware, my old coil and a wiring diagram. I

left my ballast resister on the firewall for now.

After giving the points kit more thought, I bought a backup

Ignitor III

that will be easer to change.

Advantages

of the Pertronix

Ignitor III:

-

Five times more spark energy than points

-

Multi-spark thru the entire RPM range

-

REV limit set by user, 4000 to 9000 accurate to +/- 50 RPM

-

Adaptive dwell maintains peak energy throughout the entire RPM range, reducing misfires while improving engine performance

-

Peak current level is reached just prior to spark for maximum energy without the heat build-up, increasing coil performance and module reliability

-

Adjusts spark timing at higher RPMs to compensate for the inherent electronic delay

-

Senses startup and develops more energy for quicker, easier starting

-

Senses crank orientation from either the distributor cam lobe or a PerTronix magnet sleeve

-

Thermal clad surface mount construction for high performance reliability

-

Memory safe function for user settings

-

LED user feedback for rev limit confirmation

-

Built-in reverse polarity and over current protection shuts down the system, preventing component damage

-

Legal in all 50 states and Canada (C.A.R.B. E.O. #D-57-8)

For more information on Pertronix products http://www.pertronix.com/

Adding Ignition Relay

After running the Pertronix Ignitor III for a few weeks I decided to add an ignition relay to bypass the ignition load on the ignition switch and through the relay provide the Ignitor III fused power directly from the battery lead on the starter solenoid. I wasn't having any problems feeding the power to the Ignitor III through the ignition switch but it seemed like a good idea. This change along with my headlight and cooling fan relays have off loaded all the heavy loads on the ignition switch to relays.

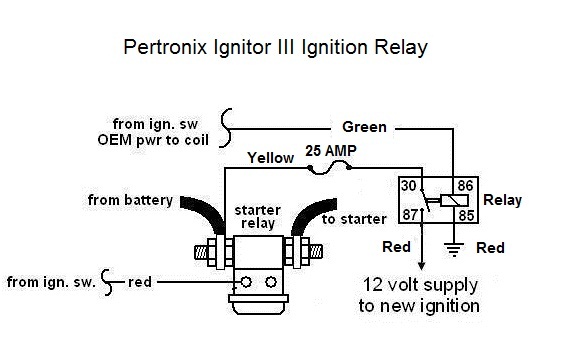

Schematic of the relay system. This drawing was provided by George Pence (Pantera International) and I modified it to meet my requirements and wire colors.

I used a Dorman #84601 30 AMP universal relay and the Buss Fuses #BP/HHG 30 AMP inline blade fuse holder that were purchased from Advance Auto. I expect that the 30 AMP rating for this application is way overkill but I used the higher AMP rating components for reliability. The 25 AMP fuse is more than needed too, but I was interested in reliability.

View of the relay installed with the parts labeled. The relay It is bolted to the location where the ballast resistor was located and I used the relay mounting bolt to ground the relay.

I added a yellow sticker to the fuse panel cover so future owners will know about the relay and location of the inline fuse. I always document changes I make to my Pantera by adding the change information and schematics to 1887s documentation manual and repair log.

November 20, 2011 Follow-up and Conclusion

After running the Pertronix Ignitor III for more than a year I can report that it works very well. Early on in the process the first unit developed an intermittent misfire problem that seemed to be heat related. Pertronix quickly replaced the unit and sent me a note indicating that it had a problem with its power logic.

During the trouble shooting process with Pertronix I added a ground wire from the Ignitor mounting plate to the intake manifold. The Pertronix tech support folks are very helpful. Overall the car starts and runs much better than my original dual point system and I think the process has been very worthwhile. I do carry a spare Ignitor III in the car just incase!